The core of our business is Precision Machining. With more than 60 years of experience, we have developed broad capabilities across multiple disciplines including CNC Swiss Turning Centers, CNC Multi-Axis Mill-Turn Machines, 5-axis Palletized Machining Centers, EDM and multiple forms of Grinding. We are experts in the machining of nickel-based aircraft alloys such as Inconel® and Hastelloy® as well as Titanium, Stainless Steel and Aluminum from bar, plate and castings.

Whether it is ultra-precise turning of tiny missile guidance and optical device components or complex 5-Axis milling of brackets for jet engines, we rely on the skill, dedication and experience of our manufacturing team to produce results that meet our standards for quality, reliability and efficiency. We routinely work to tolerances of 0.0002” (5.0 µm) in machining and 0.0001” (2.5 µm) in grinding.

With four facilities, and more than 200 CNC machines, we have one of largest installations of equipment in our industry. We have leveraged our size to develop dedicated “part family” machining cells allowing for greater focus on process refinement and increased schedule flexibility for our Customers. Our fully integrated Guaymas, Mexico facility is supported by G.S. Precision’s Engineering and Quality teams and allows for a lower cost machining option of certain products.

Multi-Axis Machining Centers

Our CNC milling machines are equipped for deep hole drilling, and many have the capability for four- and five-axis machining. They also feature pallet-changers allowing for dedicated setups, minimizing changeover and maximizing productivity. We employ the use of specialized fixtures for multi-piece machining, minimizing tool changing time and improving through-put.

Capabilities: up to 300x450x350mm (12″x18″x14″) cube

CNC Turning Centers

Our CNC turning equipment gives us the ability to manufacture components with extremely tight tolerances. We have the capability to bore holes as small as 1mm (0.040″) holding tolerances as close as 0.005mm (0.0002″) in a wide variety of materials. In addition many of our CNC Turning machines are equipped with c-axis and high-pressure coolant for deep-hole drilling. Capabilities: up to 250mm (10.0″) diameter by 300mm (12.0″) length

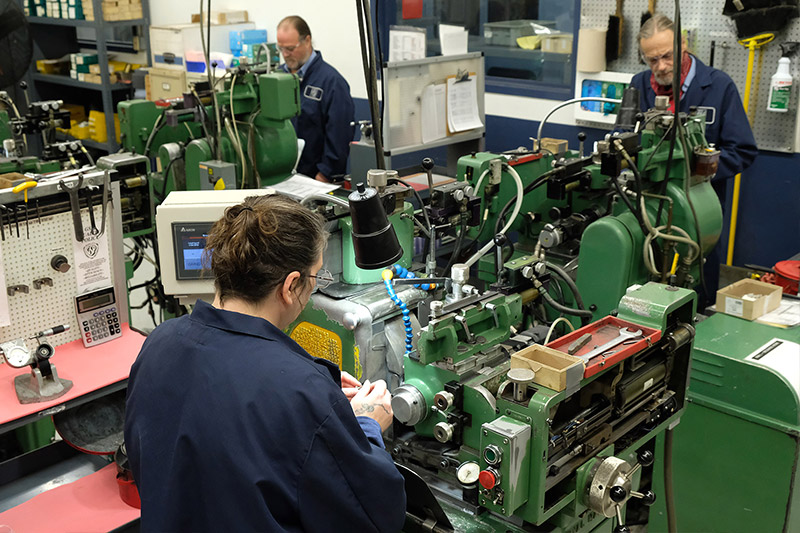

CNC Swiss

Our versatility in producing a variety of part configurations are enhanced by our CNC Swiss machines, which are equipped with C-axis sub- and main spindles. Our CNC Swiss machines are also equipped with high-pressure coolant and hydrostatic bar feeders.

Capabilities: up to 32mm (1.25″) diameter by 400mm (16.0″) length

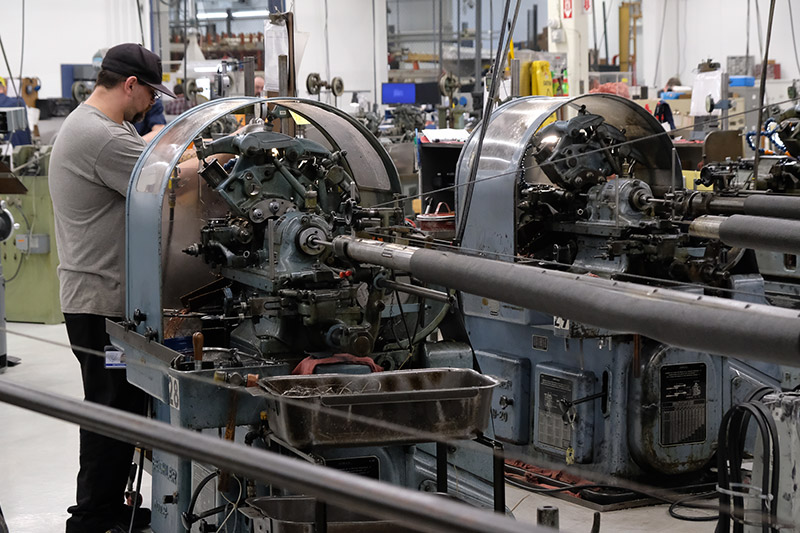

Swiss Automatics

Our more than 50 cam-operated Swiss Automatics give us the capability to precisely and efficiently machine components made of high-temperature alloys, aluminum, stainless steel and other materials. All of our cams are cut with CNC cam-cutting equipment.

Capabilities: up to 32mm (1.26″) diameter by 200mm (8.0″) length.

Precision Grinding

Our in-house grinding capabilities include cylindrical OD and ID, surface, through-feed and plunge-feed centerless, and double-disc. We are also proficient in the grinding of plasma spray coatings. We commonly hold tolerances as close as 2.5 microns (0.0001″).

EDM

We have high-precision wire and sinker EDM capabilities for producing intricate profiles and tight radius contours for parts up to a 10″ cube envelope with tolerances as close as 7.5 microns (.0003″).

Micro Deburring

We have a wide range of deburring capabilities including high-energy vibratory tumbling, grit blasting, buffing and polishing. In addition, one of our specialties is high-powered microscopic deburring up to 40x magnification.