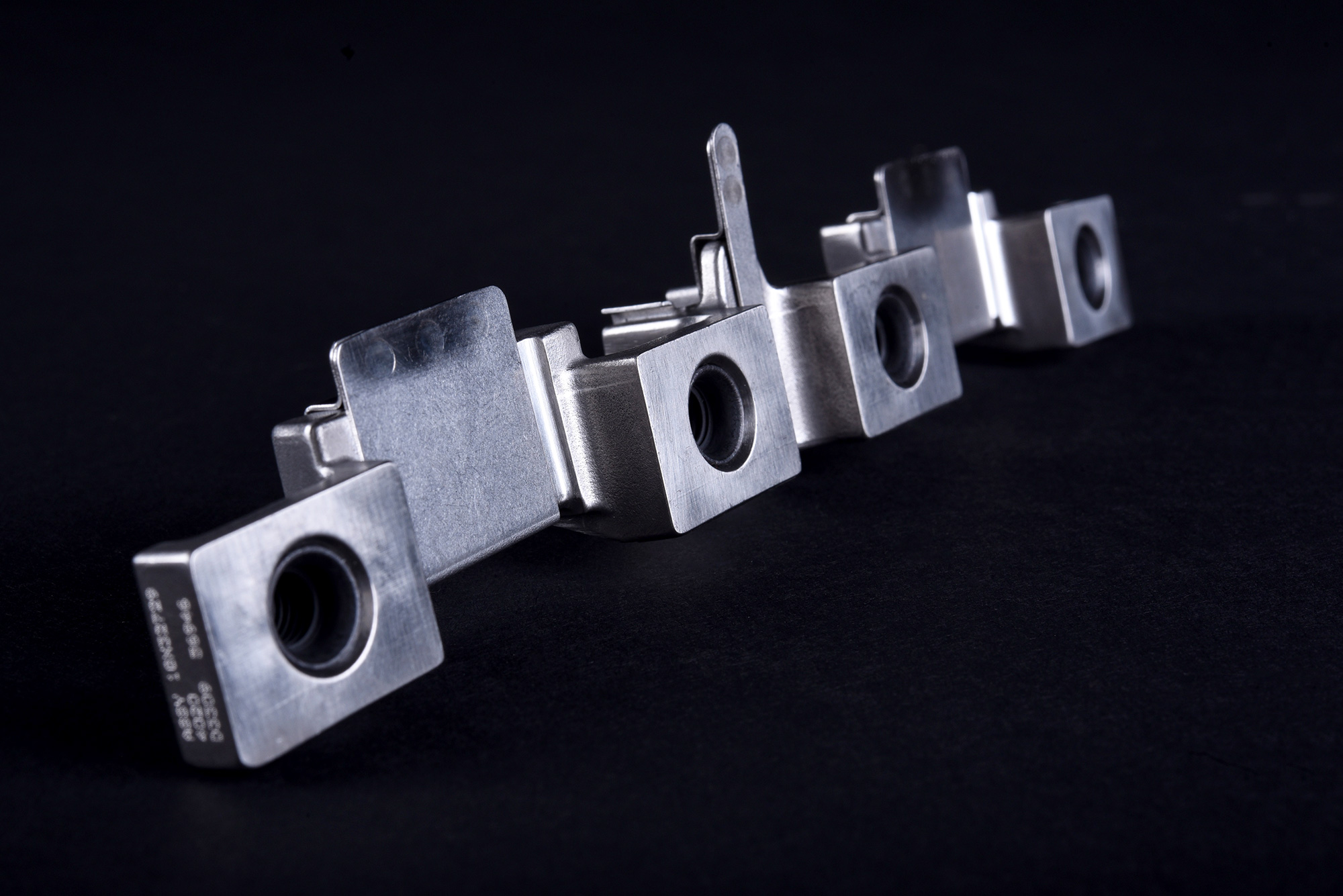

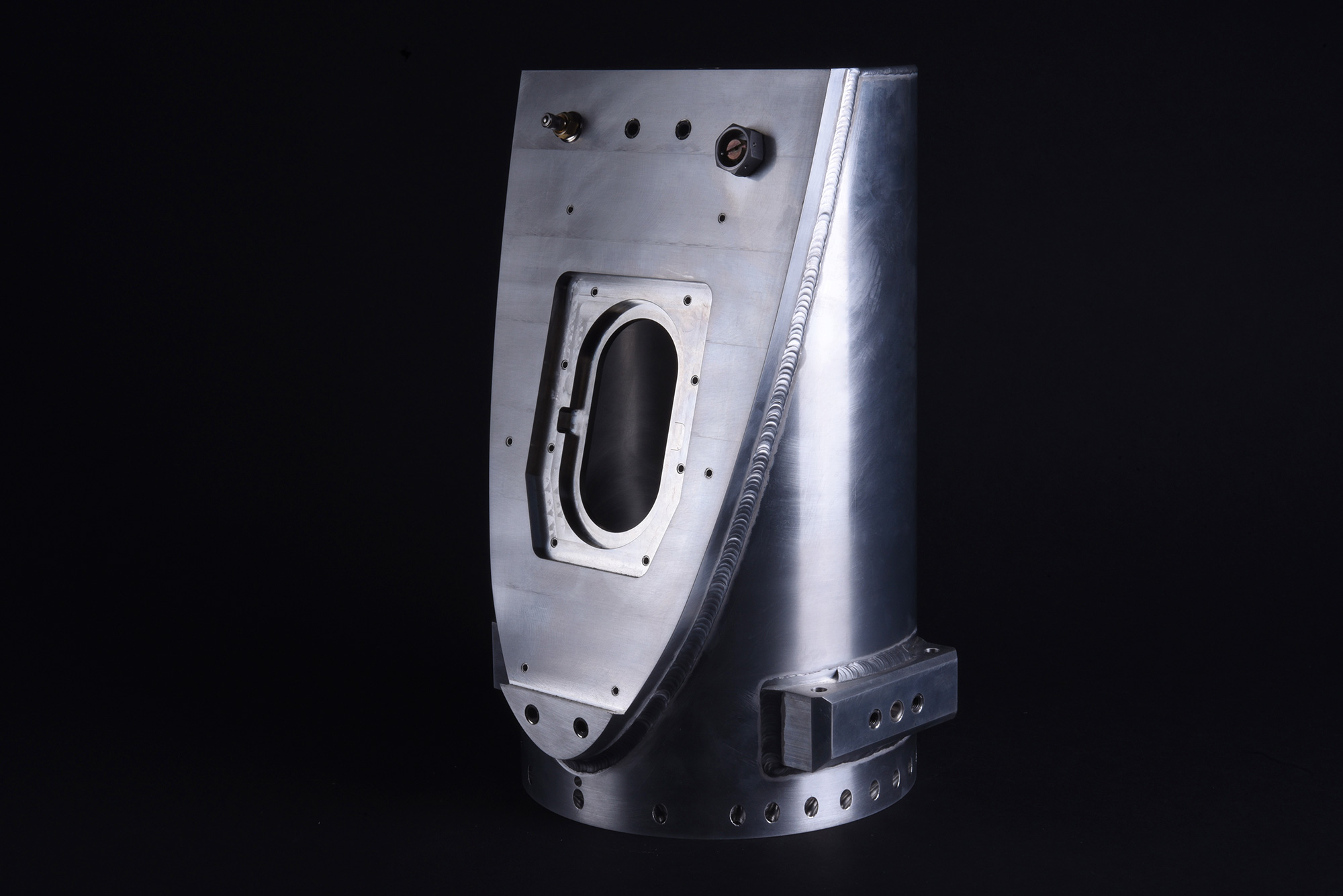

About half of G.S. Precision’s revenue is generated from products that we have assembled or welded. Our Assembly processes include mechanical operations such as the installation of Heli-coil® type thread inserts, riveted nut plates, and the press fit of wear point bushings. We also use Roller Swaging to install spherical bearings and Orbital Riveting for specific high-strength joining applications. We build assemblies that contain as few as two to more than thirty unique components. For certain product families we have developed dedicated Assembly Cells.

We rely on our NADCAP certified Welding team for their expertise in producing numerous turbine engine components including Borescope Plugs, formed Brackets and complex Tube Fitting assemblies. Our Assembly and Weld departments are able to leverage our in-house fixture design and build capabilities to optimize process efficiency and repeatability.